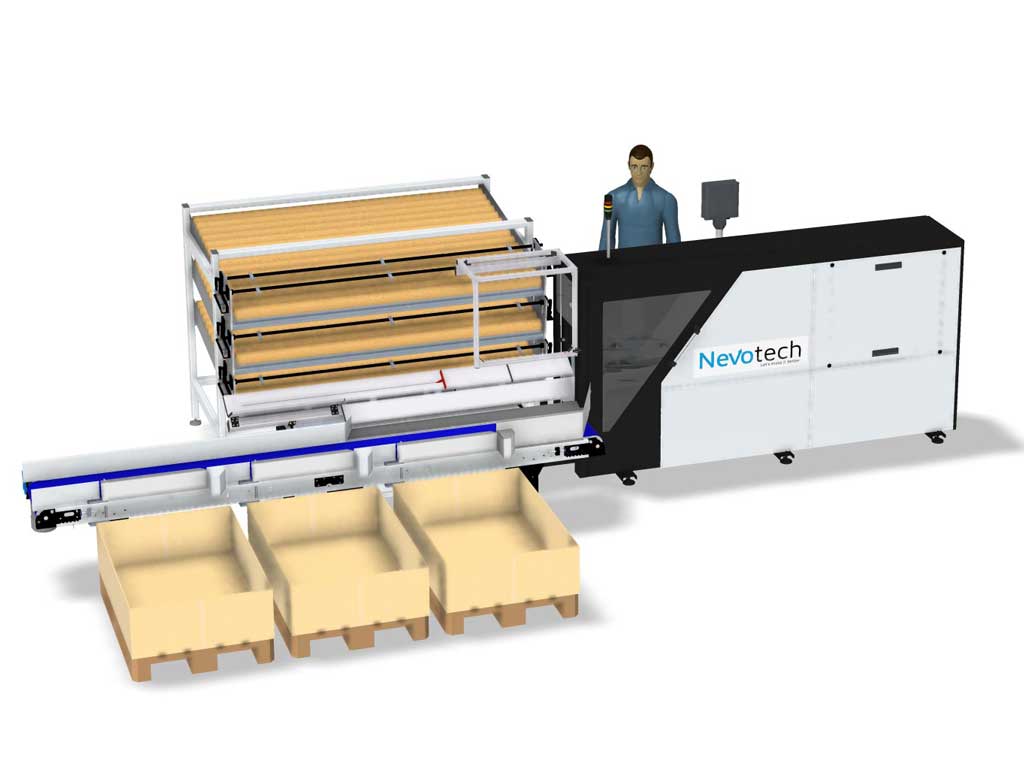

ACC project – the world’s first industrial robot for cutting cardboard cores designed in accordance with

industry 4.0 standards

The aim of the project is to develop a niche on the global market of industrial equipment used for trimming cardboard cores commonly used in industry to the required lengths. This goal will be achieved through the implementation of the business model developed under the incubation stage 1.1.1 of OP EP implemented in Eastern Poland. As a result, a dynamically developing company will be created with a product that is innovative on a global scale.

As part of the project, the world’s first industrial robot dedicated to cutting cardboard cores will be introduced to the market. According to the definition of the Oslo manual, it will be a global product innovation that will bring recipients empirically measurable benefits, including, in particular, the reduction of personnel costs and costs related to the purchase of material and the disposal of production waste.

As part of the project, a machine park will also be created enabling the internal implementation of many key elements of the robot (increasing the unit profit), as well as a marketing campaign (achieving the scale effect).

The project will be implemented by a qualified team of four people with many years of experience in the design, manufacture and sale of industrial machinery. The unchanged team created a prototype of the 4th generation of the described robot as part of the incubation process. The site of the project will be the city of Łomża.

Project value – PLN 1,306,310.00

Contribution of the European Fund – PLN 966,765.00