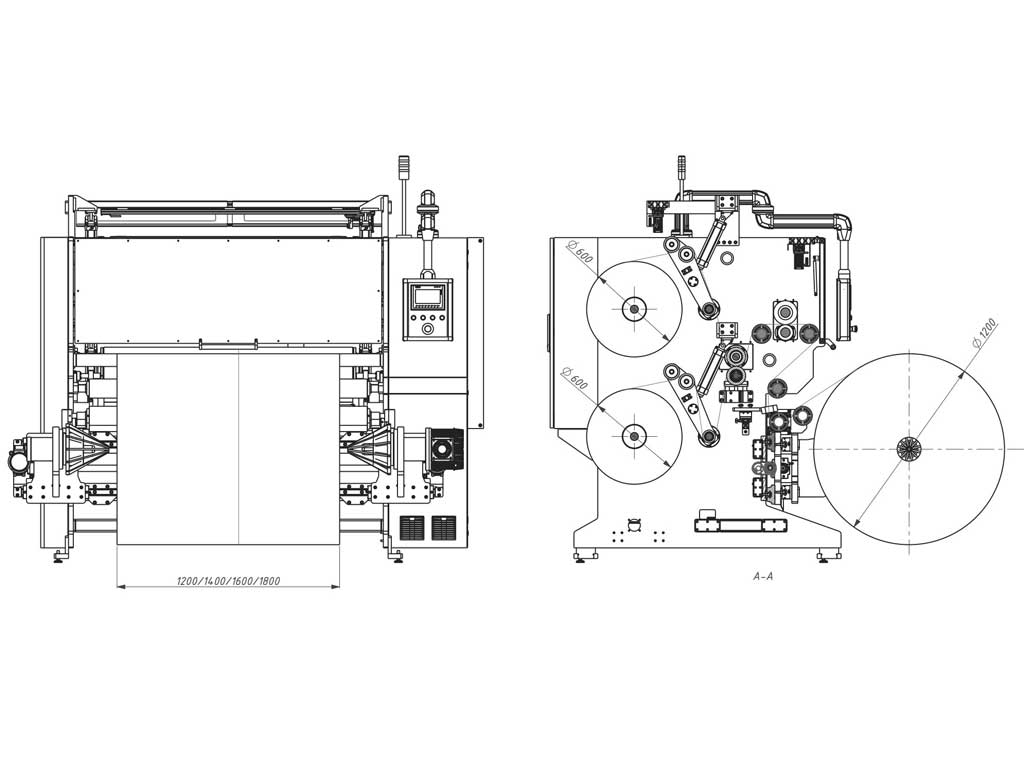

A slitter rewinder is a device commonly used in the printing, paper and plastic processing industries. Its main task is longitudinal cutting of wound materials. Depending on the equipment and the degree of automation, we distinguish a series of STANDARD and ADVANCED machines.

STANDARD series machines are dedicated to cutting non-stretchable materials such as paper, aluminum foil and PVC. The compact design allows for full usability with a small footprint of the machine.

ADVANCED series slitter rewinders are designed for highly efficient cutting and rewinding of demanding materials. Machines are equipped with, among others in systems of guiding and precise control of the web tension, automatic knife spacing systems, deionizers, pneumatic winder clamps and many other elements increasing the functionality of the device.

In the case of a slitter rewinder, the material can be fastened by means of quick-clamping holders and expansion shafts, cones as well as pneumatic or mechanical pins activated by lateral force. Collection and collection of bales of material from the machine can be done with the use of electric or hydraulic systems. Standard machines are equipped with laser indicators of the position of knives and cores, which, when positioned manually, significantly improves the entire process. Depending on the processed material, the slitter machines use scissor, razor or furrow cutting systems.

Technical data:

- Working width: 600-2600 [mm]

- Max material weight: 3000 [kg]

- Max material diameter: 2000 [mm]

- Brakes: pneumatic – RENOVA or electric drives with energy recovery

- Handles: expansion shaft / drum, pneumatic / mechanical pins, cones

- Web tension control: Automatic – proportional / strain gauges / dancing roller

- Web guiding: automatic – based on an ultrasonic or optical sensor

- Hydraulic bale lifting: via the control panel

- Cutting system: scissor / razor / crushing

- Positioning the knives: manual or automatic

- Laser pointers – material, knives and cores positioning

- Touch panel: SIEMENS – KTP700 or

It is possible to make the machine according to individual customer requirements.